Warehouse Management Software (WMS)

Our WMS software provides the foundation from which we build your warehouse or distribution solution. We built this software solution based on years of real-world, hands-on experience. This approach resulted in a more productive, accurate, scalable, and efficient solution.

What is a Warehouse Management System?

A WMS, or warehouse management system, is a key part of the supply chain and primarily aims to control the movement and storage of materials within a warehouse or distribution center and process the associated transactions.

From inventory control, shipping and receiving, to order fulfillment…

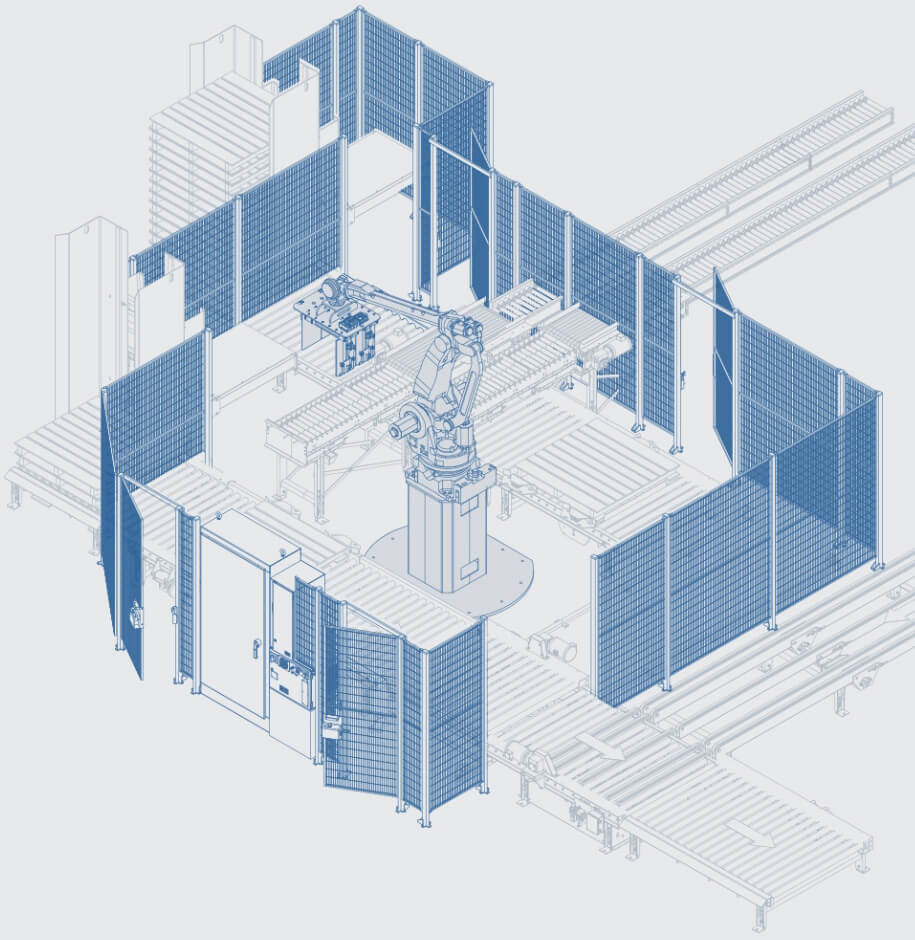

A WMS is vital to improving the efficiency of a company's warehouse operations. Our WMS software modules can be configured and customized to fit the need of any company. By combining a Warehouse Management System with wireless-mobile-devices, bar code and/or radio frequency identification (RFID) technology, and various picking technologies like Voice, Pick-to-Light, Carousels or A-frames, we can help increase operational efficiencies while enhancing your customer experience through more accurate order fulfillment. Key functionality includes the following…

Receiving

Products are analyzed to determine the best storage location based on historical demand and facility layout. Quality checks are a standard function to ensure product delivered matches purchase orders.

Quality Control

Your QC requirements can be built-in as standard functionality within our WMS solution. Inspection requirements, instructions necessary to approve or reject products received. Defective products can be quarantined until final disposition.

Order Processing

We provide functionality for Wave or Waveless picking. Grouping orders in a series of waves to be picked throughout the day is a standard function of our WMS. Our software provides the control and visibility you need for effective planning, management, and execution.

Picking

There are numerous methods utilized today for picking operations. We streamline the order picking process by combining intelligent picking methods with automated systems. We support all types of picking; Pick-To-Light, RF Scanners, A-Frames, Voice-Picking, etc. Our Double Check provides an intelligent process for validating picking accuracy and optimizing the quality check process.

Pack & Ship

With the DCX Software Suite, one can develop packing, checking and shipping systems that not only operate more efficiently, but eliminate virtually all picking errors.

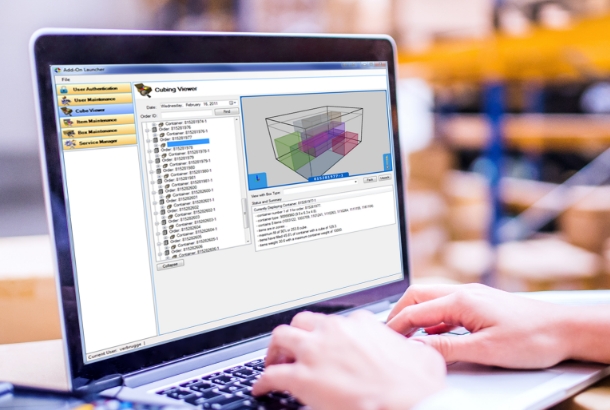

Packing & Cubing

Featuring our True 3D Collision Detection, our innovative Cubing Module provides a unique set of tools that not only determine the best shipping container for each order, but configures its optimal packing arrangement while providing the operator with a full 3D Image.

Double Checking

This flexible and highly customizable module allows one to create intelligent processes for validating picking accuracy and optimizing the quality check process.

Sorting & Carrier Selection

The DCX Software Suite provides configurable pack slip design via SQL Reporting as well as integration with shipper and freight manifest systems that rate shop across multiple carriers to select the lowest cost freight carrier for each specific package.