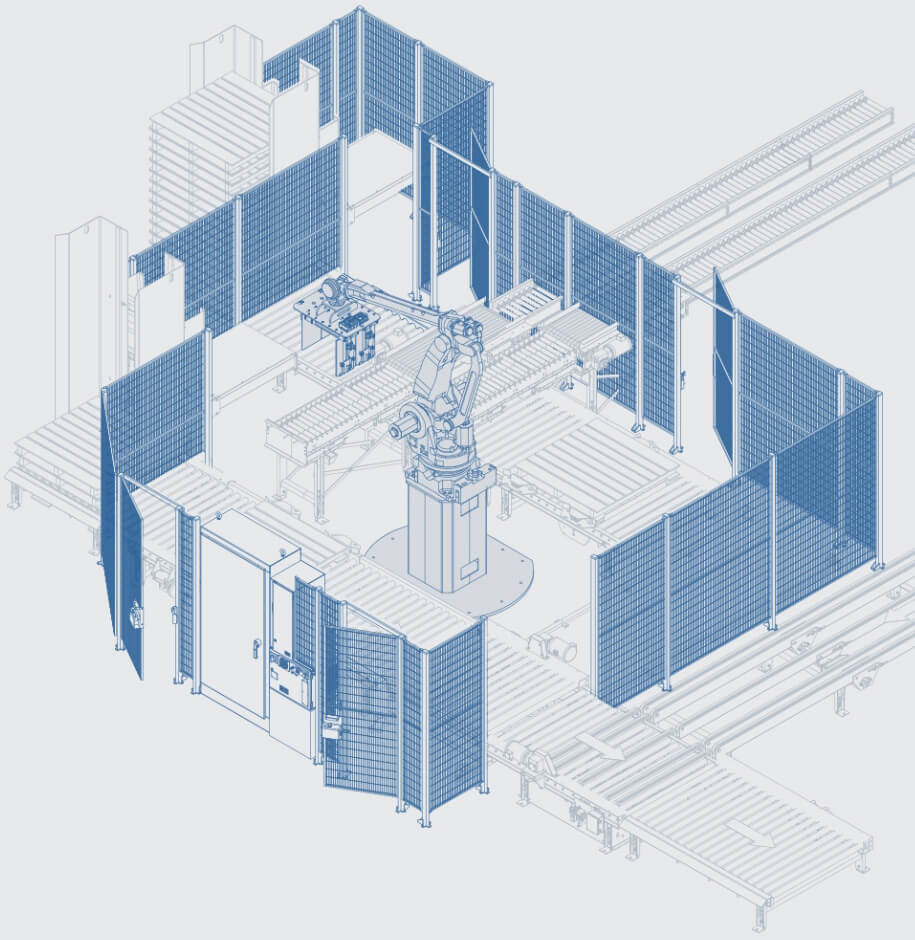

Infeed Systems

Every robotic palletizer requires some method for getting products into the cell and MMCI’s engineering team has the experience to ensure that this process is designed to be efficient, safe and reliable.

Standard Infeed Conveyors

Most robotic cells will be equipped with zero pressure, 24-volt conveyors that limit product touching and feature accumulation zones pre-programmed to operate in our standard robotic palletizing models.

Benefits

- Non-contact, zero pressure accumulation protects products

- Energy efficient

- Accepts multiple sizes and weights

- Quiet operation

Customization

While our Quick-Ship Palletizers feature a standard conveying solution for bringing products into the cell, our team will often apply intelligent engineering, smart technology or highly customized options to meet the specific needs of our customers.